Autocad Plant PFD: 5 Key Steps to Create Accurate Diagrams

Why AutoCAD Plant 3D is the Smart Choice for Modern Plant Design

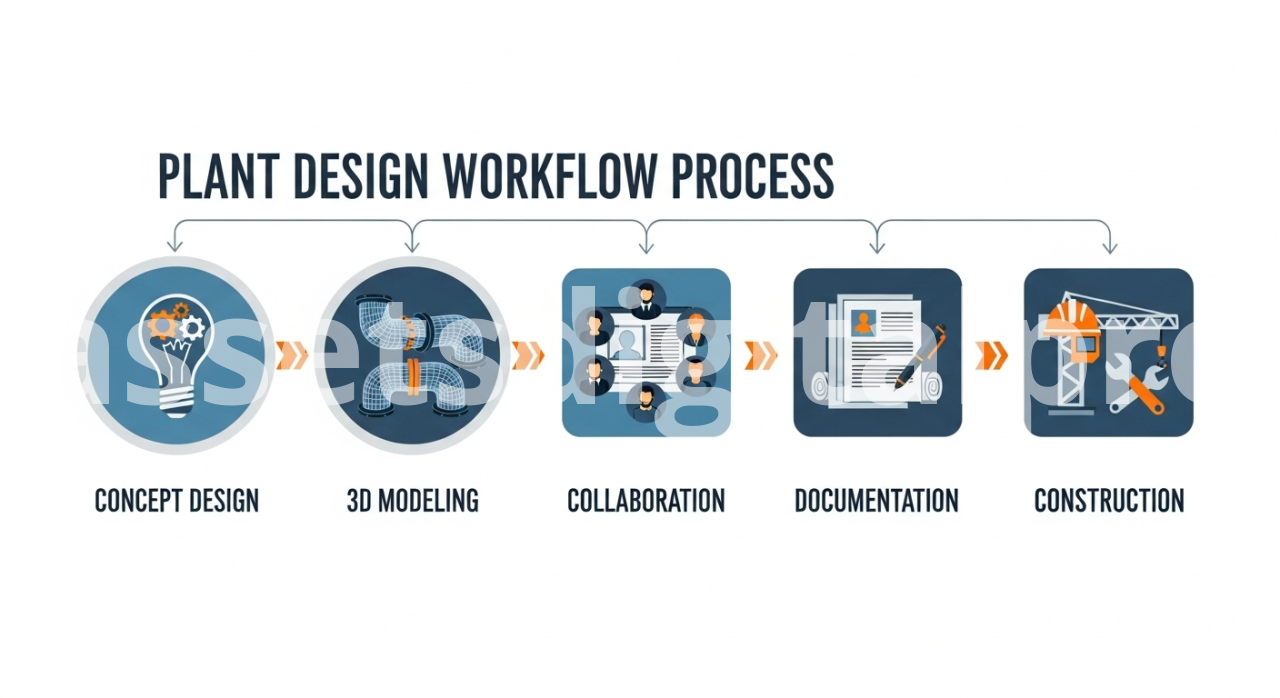

In today's competitive industrial landscape, AutoCAD plant PFD design has become increasingly complex, demanding sophisticated tools that can handle intricate workflows while maintaining precision and efficiency. The traditional approach to plant PFD AutoCAD development often presents significant challenges that can derail project timelines and inflate costs.

The Evolving Landscape of Plant Design

Modern plant design faces numerous obstacles that can significantly impact project success. Preventable waste emerges when design iterations lack coordination, leading to costly rework and material inefficiencies. Disjointed workflows create communication gaps between disciplines, resulting in inconsistent design decisions and delayed project milestones. When engineering data remains scattered across multiple platforms, teams struggle to access critical information when needed most.

The complexity of retrofits, upgrades, and expansions adds another layer of difficulty. Legacy systems often lack the documentation depth required for seamless integration with new components, while project visibility remains limited when stakeholders cannot access real-time design updates and progress reports.

How Plant 3D Addresses These Challenges

AutoCAD plant design software emerges as a powerful solution specifically engineered to tackle these industry-wide challenges. This comprehensive platform integrates intelligent modeling capabilities with advanced automation tools, creating a unified environment that accelerates time to market while maintaining the highest standards of accuracy and consistency.

The software's user-friendly interface and intuitive design methodology make transitions seamless for teams already familiar with AutoCAD environments. By leveraging Plant 3D's intelligent systems, engineering teams can focus on creative problem-solving rather than repetitive manual tasks, ultimately delivering superior results in shorter timeframes.

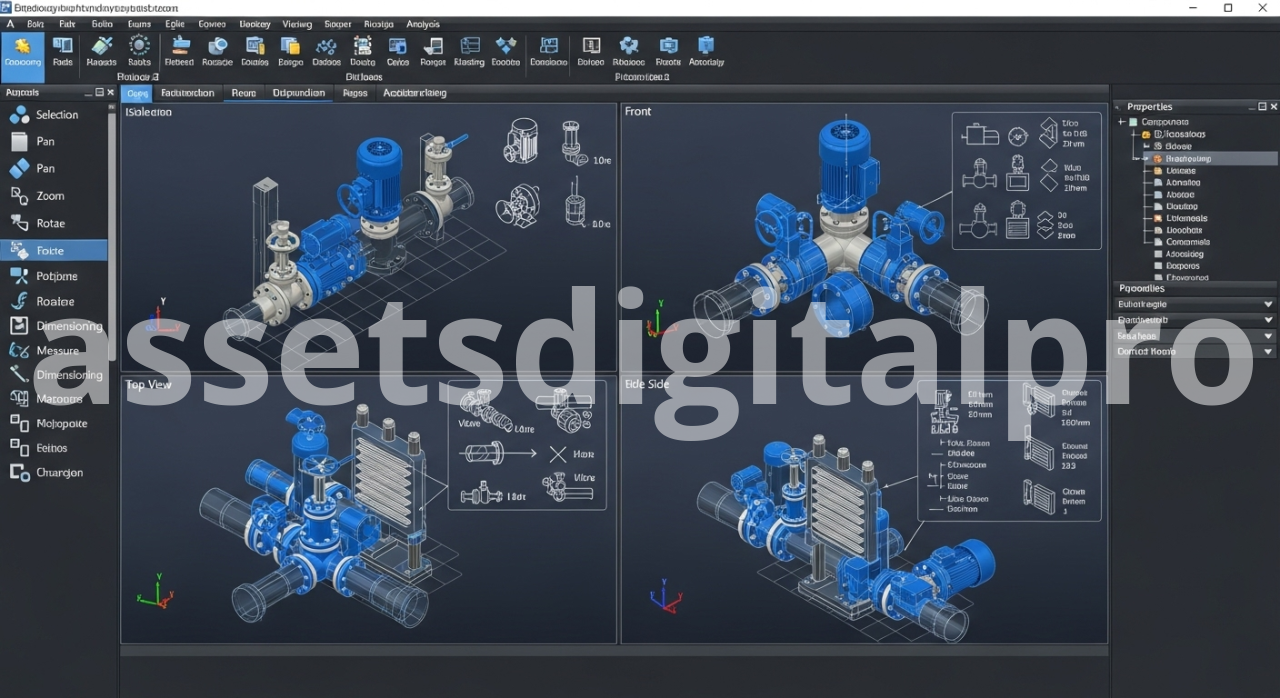

Core Capabilities: Unpacking the Power of AutoCAD Plant 3D

Plant 3D's robust feature set addresses the specific needs of modern plant design professionals, providing comprehensive tools that streamline complex workflows while ensuring precision and consistency across all project phases.

Intelligent Plant Modeling for Precision and Consistency

The foundation of effective AutoCAD plant PFD development lies in intelligent modeling capabilities that adapt dynamically to design changes. Parametric components form the backbone of this system, automatically adjusting to modifications while maintaining design integrity and eliminating the inconsistencies commonly associated with manual input methods.

Spec-driven piping systems enforce material specifications and design constraints automatically, significantly reducing the need for manual checks and subsequent revisions. This intelligent approach ensures that every component selection aligns with project requirements and industry standards, preventing costly specification errors downstream.

Automated tagging functionality maintains consistency throughout the design process, ensuring that every component receives appropriate identification according to established naming conventions. The system's accurate modeling capabilities facilitate precise piping design and routing, with model dimensions that reflect real-world specifications with exceptional fidelity.

The software excels at creating and modifying critical diagrams, including P&ID diagrams and isometric piping drawings that form the foundation of successful plant construction projects. These diagrams maintain live connections to the 3D model, ensuring that any design changes propagate automatically throughout all related documentation.

Streamlined Design Workflows and Automation

Plant 3D dramatically accelerates the design process through comprehensive automation features that eliminate repetitive tasks and reduce the potential for human error. The software's automated task execution capabilities handle complex operations like isometric drawing generation, Bill of Materials (BOM) extraction, and piping route optimization with minimal user intervention.

The comprehensive toolset enables extraction of high-quality piping isometrics and orthographic drawings, with isometric drawings containing the detailed information necessary for field installation. This level of detail ensures that construction teams have access to precise specifications without requiring additional documentation efforts.

The user-friendly interface provides intuitive commands for creating complex 3D models, while specialized tools for 3D piping slope adjustments allow engineers to fine-tune designs with unprecedented ease. Standard libraries offer extensive "out-of-the-box" content, including comprehensive symbol libraries for P&ID creation that comply with industry standards.

Information management capabilities enable efficient handling of extensive engineering data, with rapid report generation for valves, PLC I/O systems, equipment specifications, and instrument inventories. The system's flexibility allows users to easily modify process flow visualization and instrumentation options, while adjustable line weights and scales ensure optimal drawing presentation.

Built-in error checking functionality navigates directly to inconsistencies within drawings, highlighting potential issues before they can impact project timelines or construction quality.

Enhancing Collaboration and Data Management with Plant 3D

Effective collaboration and robust data management form the cornerstone of successful large-scale plant design projects, where multiple disciplines must work together seamlessly while maintaining data integrity throughout the project lifecycle.

Integrated Multi-Discipline Collaboration

Plant 3D breaks down traditional silos by enabling real-time collaboration through centralized model access and shared data repositories. This integrated approach ensures that all team members work with current information, eliminating the confusion and errors associated with outdated file versions.

Cloud-based integration with Autodesk Construction Cloud (formerly BIM 360) allows stakeholders to review, comment, and update designs without the delays associated with traditional file sharing methods. This streamlined coordination provides accurate, up-to-date information to procurement and construction teams, ensuring that downstream activities proceed smoothly.

The worksharing capabilities enable multiple designers to work simultaneously within the same model, maximizing productivity while maintaining design consistency. Integration with Navisworks provides comprehensive 3D review capabilities, allowing teams to visualize complex assemblies and identify potential conflicts before construction begins.

Supplier integration features accommodate 3D blocks directly into plant models, ensuring that vendor-specific components are accurately represented throughout the design process. The ability to link 3D piping models with 2D AutoCAD drawings maintains consistency between different drawing types while supporting established workflows.

Comprehensive support for multiple information exchange formats ensures compatibility with existing systems and facilitates seamless data transfer between different software platforms and project stakeholders.

Deep Dive into AutoCAD Plant 3D with Autodesk Vault for Robust Data Management

The integration of plant PFD AutoCAD with Autodesk Vault addresses critical needs for enhanced security, comprehensive versioning, reliable check-out and check-in procedures, and seamless multi-office collaboration capabilities that modern engineering projects demand.

Vault functions as a sophisticated Product Data Management (PDM) tool that extends far beyond simple version control. This comprehensive system provides workflow security and file control through revision management and complete lifecycle oversight, ensuring that every project element maintains proper documentation and traceability.

The Vault environment consists of three primary components: the Vault Client interface, the Vault Server containing both SQL Server Database and File Store components, and individual local workspaces that provide responsive access to project data.

Key Vault functions include the check-in and check-out mechanism that ensures data integrity by locking items during editing, preventing conflicting modifications. The organized tree structure provides a familiar Windows Explorer-style interface within the Vault Client, making navigation intuitive for users transitioning from traditional file management systems.

Version management creates new versions automatically upon check-in, maintaining complete change histories. Revision schemes support alphabetic, numeric, or custom formatting that integrates with comprehensive file lifecycles including Work In Progress, For Review, Released, Quick Change, and Obsolete states.

Categories and rules enable logical grouping of objects with assigned behaviors, user-defined properties, and specific lifecycle definitions. Vault reporting leverages metadata to generate comprehensive project status reports accessible to stakeholders regardless of their Plant 3D expertise.

AutoCAD plant environments support multiple configuration options. Single Vault with Single Plant Database configurations provide enhanced security and data management with performance improvements through local project structures. Replicated Vault with Single Plant Database configurations improve performance for remote users through locally stored files.

For organizations requiring maximum performance in challenging network conditions, Replicated Vault with Replicated Plant Project configurations replicate the entire Plant 3D database, requiring SQL Server Standard edition 2016 SP1 or later for Change Data Capture (CDC) functionality.

Managing Plant-Vault projects requires adherence to critical best practices including file management through Plant Project Manager, regular check-in procedures, read-only access when not actively editing, and proper Xref management within the same project and vault structure. Common pitfalls include avoiding Vault Client for project management, preventing File Explorer modifications, maintaining online connectivity, and preserving local workspace integrity.

Backup and restore procedures require synchronized restoration of both Plant database and Vault to identical time points for complete recovery capability. SQL Server configuration considerations include separate database instances for Vault, with flexibility for hosting project master databases on different server instances.

Optimizing Your Plant 3D Workflow: Advanced Tips & Solutions

Advanced workflow optimization techniques enable teams to maximize Plant 3D's capabilities while addressing specific challenges that arise in complex industrial projects.

Best Practices for Large Projects

Large-scale projects benefit from strategic division into multiple drawing files, facilitating team collaboration and creating manageable data sets that improve system performance and reduce complexity. Extensive use of External References (XREFs) enables multiple disciplines to work concurrently while maintaining data integrity and coordination.

Smaller file structures minimize corruption impact, as individual files become easier to diagnose and repair when issues arise, preventing widespread project disruption.

Troubleshooting Common Plant 3D Issues

BOM export challenges often arise when components span multiple sheets due to SQL table classification systems. Components may be classified differently than expected, such as check valves appearing as hand valves and engineering items. Leveraging the data manager's advanced filtering capabilities and custom report creation addresses these organizational challenges effectively.

Imperial and metric component connection errors require specific attention to unit consistency throughout the project. System requirements and PowerPack features provide additional tools for managing these compatibility challenges.

Valve operator symbols in isometric drawings depend on SKEY assignments and IsoSkeyAcadBlockMap.xml configuration. Understanding these control mechanisms enables custom configuration for specific project requirements.

Pipe routing limitations may restrict incremental routing distances, requiring workflow adjustments and alternative approaches for complex routing scenarios. Sloped piping benefits from Plant 3D's intuitive 3D slope adjustment tools, providing precise control over elevation changes throughout piping runs.

Custom component modeling addresses specialized requirements like custom miter welds or specific equipment such as control valves and depropanizer condensers. These specialized components require careful attention to modeling standards and integration with existing component libraries.

Powering Up Plant 3D with Add-ins and Training

PowerPack for Plant 3D provides advanced tools that enhance control, accuracy, and efficiency through specialized features like AutoSheet for significant time savings during drawing production phases.

Comprehensive training programs ensure teams maximize their Plant 3D investment through expert instruction covering project setup, steel structure design, piping design methodology, customization techniques, data management best practices, and cloud collaboration workflows.

Operational and functional transformation programs like "UP & Ready" and "EmpowerUp" provide tailored training and mentoring that addresses specific organizational needs and workflows.

Custom software solutions including specialized templates, database connections, and third-party plugins streamline workflows while improving interoperability with existing systems and established procedures.

Conclusion: Accelerate Project Success with AutoCAD Plant 3D

AutoCAD plant PFD design reaches its full potential when teams leverage Plant 3D's comprehensive capabilities for precise, data-driven design development, seamless project execution, and optimal resource utilization across all project phases.

The software empowers engineering teams to deliver superior results through intelligent automation, robust collaboration features, and comprehensive data management capabilities that address the complex challenges facing modern industrial design projects.

Success with Plant 3D often depends on experienced technology partnerships that provide specialized functionality and overcome complex data management scenarios. Effective partnerships emphasize clear communication, project clarity, and organizational alignment to ensure optimal outcomes.

Whether you're exploring advanced training opportunities, investigating custom solutions, or seeking expert consultation for Plant Roadmap Workshop development, investing in AutoCAD plant expertise provides the foundation for sustained competitive advantage in today's demanding industrial design environment.

Related Posts

- Comments

English

English

Arabic

Arabic

![Unreal Engine 6: The Ultimate Guide to Release Date Rumors, Features & Predictions [Updated 2025]](https://assetsdigitalpro.com/uploads/blog/202505/img_thumb_6816b4d8a209f0-34611535.png)